The Dawn of Autonomous Machines in Hazardous Worksites

The advent of autonomous machines has revolutionized various industries, particularly those involving hazardous work environments. These machines, equipped with sophisticated technologies such as artificial intelligence, robotics, and advanced sensors, are transforming the way we approach tasks in dangerous settings. From mining to construction, and demolition to firefighting, autonomous machines are proving to be invaluable assets.

Enhancing Safety and Reducing Risk

One of the most significant advantages of autonomous machines in hazardous worksites is their ability to enhance safety. These machines can perform tasks that would be perilous for human workers, thereby minimizing the risk of injuries and fatalities. For instance, in environments with toxic chemicals or unstable structures, autonomous robots can be deployed to conduct inspections, collect samples, or even perform repair work, without putting human lives in jeopardy.

Example: In the mining industry, autonomous vehicles are used to transport materials through narrow tunnels and steep terrains. These vehicles are equipped with sensors that allow them to navigate safely, detect obstacles, and avoid collisions, ensuring the safety of the entire operation.

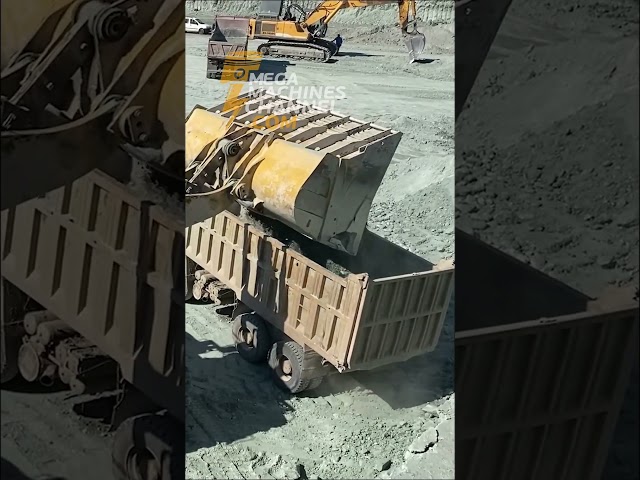

Improving Efficiency and Productivity

Autonomous machines are designed to operate with a high degree of precision and consistency, which significantly improves efficiency and productivity. They can work continuously without breaks, fatigue, or human error, leading to increased output and reduced operation times. Additionally, these machines can be programmed to perform repetitive tasks, freeing human workers to focus on more complex and strategic activities.

Example: In construction, autonomous equipment such as bulldozers and excavators can grade land, move earth, and lay foundations with impeccable accuracy. This not only speeds up the construction process but also ensures that the work is carried out to exact specifications.

Cost-Effectiveness

While the initial investment in autonomous machines can be substantial, the long-term financial benefits are significant. By reducing the need for human labor in dangerous environments, companies can lower their labor costs and minimize expenses related to accidents and compensation claims. Moreover, the enhanced efficiency and productivity brought about by these machines result in higher output and profitability.

Table: Cost Comparison

| Category | Human Labor | Autonomous Machines |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance | Moderate | Moderate |

| Operating Efficiency | Variable | High |

| Risk of Accidents | High | Low |

| Long-Term Savings | Low | High |

Advanced Data Collection and Analysis

Autonomous machines are equipped with sensors and data collection tools that provide valuable insights into worksite conditions and operational efficiency. This data can be analyzed in real-time to detect potential hazards, optimize workflows, and make informed decisions. For example, autonomous drones equipped with high-resolution cameras and thermal imaging sensors can survey and monitor large areas, providing detailed reports on environmental conditions and structural integrity.

Such advanced data collection capabilities allow for proactive maintenance and timely interventions, preventing accidents and reducing downtime.

Environmental Monitoring and Sustainability

Autonomous machines are playing a crucial role in promoting environmental sustainability in hazardous worksites. These machines are often designed to operate with minimal emissions and energy consumption. Additionally, their precision and efficiency mean that resources are utilized more effectively, resulting in less waste and lower environmental impact.

Example: In agricultural settings, autonomous tractors and harvesters use precise GPS and sensor data to ensure that crops are planted, tended, and harvested with minimal waste and maximum yield. This not only enhances productivity but also promotes sustainable farming practices.

Versatility and Adaptability

One of the standout features of autonomous machines is their versatility. These machines can be programmed and reprogrammed to perform a wide range of tasks in different hazardous environments. Their adaptability makes them suitable for various industries and applications, from disaster response and recovery to space exploration and underwater missions.

Example: In disaster response, autonomous robots equipped with cameras and sensors can navigate through rubble and debris to locate survivors and assess structural damage, providing critical information to rescue teams.

Technological Innovations Driving Autonomous Machines

The continuous advancement in technology is driving the development and deployment of autonomous machines. Innovations in artificial intelligence, machine learning, robotics, and sensor technology are enabling these machines to become more intelligent, efficient, and capable.

Artificial intelligence and machine learning algorithms allow autonomous machines to learn from their experiences, adapt to changing environments, and improve their performance over time. Robotics advancements are enhancing the physical capabilities of these machines, enabling them to perform complex tasks with greater dexterity and precision. Sensor technology is providing these machines with enhanced perception and situational awareness, allowing them to make real-time decisions and navigate challenging environments safely.

Ethical and Regulatory Considerations

As the use of autonomous machines in hazardous worksites continues to grow, there are important ethical and regulatory considerations that must be addressed. Ensuring the safety and reliability of these machines is paramount, and rigorous testing and certification processes are essential. Additionally, there are concerns regarding the displacement of human workers and the potential loss of jobs. It is crucial to strike a balance between leveraging the benefits of autonomous machines and addressing the social and economic impacts on the workforce.

Governments and regulatory bodies must establish clear guidelines and standards for the development, deployment, and operation of autonomous machines. This includes ensuring transparency in decision-making processes, protecting data privacy, and promoting equitable access to the benefits of this technology.

The Future of Autonomous Machines in Hazardous Worksites

The future of autonomous machines in hazardous worksites is promising. As technology continues to advance, these machines will become more sophisticated, capable, and accessible. In the coming years, we can expect to see increased integration of autonomous machines in various industries, leading to safer, more efficient, and sustainable operations.

Furthermore, the collaboration between human workers and autonomous machines will continue to evolve. Instead of replacing humans, these machines will complement human efforts, taking on dangerous and repetitive tasks while allowing humans to focus on decision-making, creativity, and strategic planning.

In conclusion, the adoption of autonomous machines in hazardous worksites offers numerous advantages, from enhancing safety and efficiency to promoting sustainability and innovation. As we embrace this technological revolution, it is essential to navigate the associated challenges and ensure that the benefits are shared broadly across society.